We could say that CNC is an electronic driver of the Cutting System based on the configurations by the user and the profiles of the parts to be worked on fed into the system before the beginning of the job. Making use of built-in electronic and software automation, CNC can control the cutting process calculating all available parameters, both the ones determined by the Cutting code (G-Code) fed into it beforehand and the real-time cutting data provided by the relevant sensors. It adjusts the proper gas mixture and velocity, the feed rate and the torch movement along the three axes, and the power of the Source. The cutting process is automatically continuously adjusted in the best way, much better than by the most experienced operator.

The idea behind CNC cutting is to allow a computer to control the torch head making clean sharp cuts. Absolute precision is possible through CNC machining, consequently hand-held torches are to be avoided; the cutter has been built into the table. Modern CNC plasma equipment is capable of multi-axis cutting of thick material, allowing opportunities for complex welding seams on CNC welding equipment that is not possible otherwise.

Fixed equipment as compared to portable ones have the option to include heavy cutting energy sources to cut much thicker material. They also allow opportunities for complex welding processes. More complex state-of-the-art technologies allow more elaborate cuts with thinner kerf and greater thickness. Inverter plasma cutters have replaced the analog ones. They rectify the energy supply to DC which is fed into a high frequency inverter 10 kHz to 200 kHz which allows for reduced size and weight.

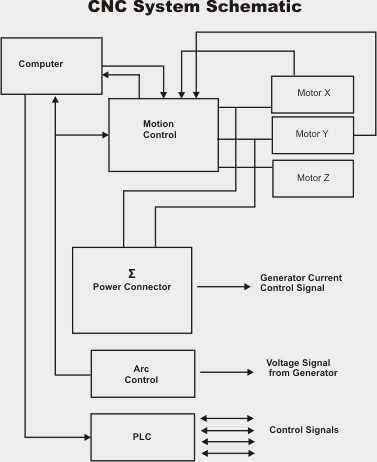

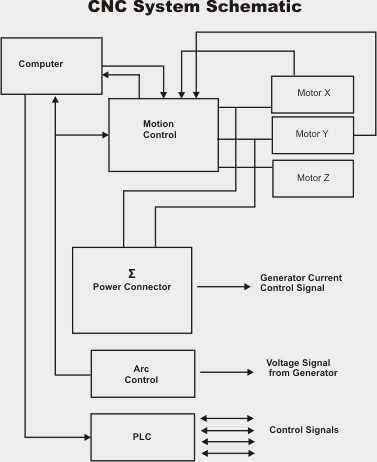

Such a CNC should be similar to the ones controlling Laser Cutting processes. A modern CNC should have Response time less than 0.5msec servoloop because it must be in a position to respond faster than the cutting process it controls. It should also have linear control over the current of the Source for it to be adjustable to the Feed Rate recommended.

The cutting current must be controllable to automatically lower amperage whenever the cutting speed slows down. If it is not, a bigger quantity of material will be melted and removed from the actual point than necessary to achieve an optimal cut. At the same time, a minimum Plasma density should be maintained, for the arc to stay alive and the cutting process active. The whole system must be balanced to avoid time consuming and consumables damaging interruptions. CNC control over the source current is also indispensable for Pulse Piercing to be feasible.

The cutting energy is controlled by being delivered in high-and-low-current pulses, enabling the reduction of the volume of metal melted. This way we avoid risking molten metal spattering over the nozzle and sensors and destroying them. Pulse piercing is an important tell-tale trial for CNC suitability for High Definition Plasma cutting.

Cut quality depends to a high degree on the distance between the torch tip (nozzle) and the surface of the sheet we work on. The Plasma Arc is not cylindrical, it gets narrower in its upper and lower edges; consequently, when we cut too high the cut is performed by its lower edge and vice versa. In both cases the “sides” of the cut are not square. Please see our photo to the right: the torch is too high and the cut is “conical”. It is only when the cut is performed by the middle section of the Arc that we achieve optimal cuts. Here the presence of a digital Arc Control system interconnected to the CNC is absolutely important. It must be able to interact with the CNC for the ideal Torch Height to be maintained regardless the torch velocity changes and eventual holes in the job.

In this case, the extra cost for a High Definition Plasma Cutting system is simply not justifiable because the end result is not up to the High Definition standards. The cutting machine has a lot of built-in quality potential which cannot be taken full advantage of.

All electronic subsystems and the relevant software should be absolutely matched and fine-adjusted to one another to achieve the best results possible. Here we are talking about intercommunication and response times in the order of less than one thousand of a second! Subsystem co-ordination on such a level is achieved only by adjustments to the minutest detail and is only possible for manufacturers having a vertical manufacturing Know-How of the Plasma High Definition and Laser Cutting Systems. Lack of this Know-How cannot be remedied by outsourcing, regardless the quality of the parts acquired this way, as it makes fine adjustment impossible to achieve, resulting in incompatibilities and wrong configuration; results inferior to the ones theoretically expected are a direct consequence of such minor programming inconsistencies!